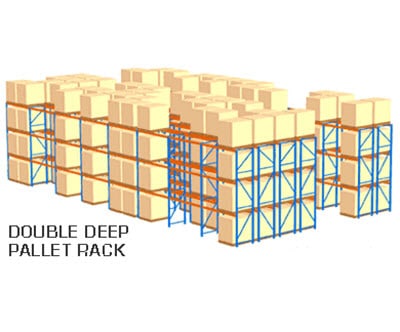

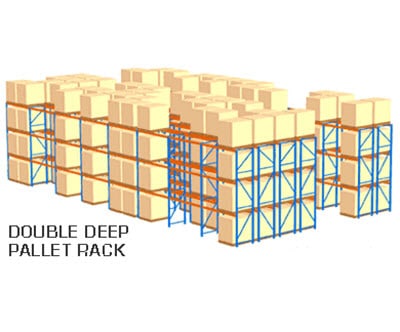

Another pallet is then placed on the front rack unit eliminating the need for an aisle between the two storage racks.

Double deep racking pallet handling systems.

But pallets are now stored two rows deep instead of one.

This increases by up to 25.

Each pick slot has a front and a back pallet.

The most common forklift used for double deep handing is a reach truck.

Using a deep reach lift truck the operator places a pallet onto the deepest rack structure.

Double deep is similar to selective racking.

Double deep is a variation of apr racking as the basic components are the same.

A run may consist of a couple of bays of racking along the storage wall or a several hundred.

Double deep pallet racks consist of two standard selective racks set up back to back creating the double deep pallet storage system.

Eliminating the need for an aisle between two storage racks.

Ridg u rak double deep pallet rack systems place one row of 100 selective pallet rack behind another.

Double deep pallet racking systems require deep reach lift trucks.

Ideal for businesses with a minimal range of products who deliver in high volumes.

How do i know how much pallet racking i need.

Practical for high volume single skus required for rapid despatch store up to four pallets deep for swift dispatch of large single sku orders.

This provides access to two pallets from the same side of the aisle with one placed behind the other towards the back of the pallet rack the illustrations below will give you a better idea of how the load units are arranged.

One popular way to design a pallet rack storage layout is to start with a given distance of racking often referred to as a run the distance of a run represents available floor space on which a continuous stretch of pallet racking will be installed.

The double entry aisle offers easy access through dual pantograph or sliding fork attachments.

Although the main advantage of the double deep system i e the ability to save space due to the need.

This type of racking therefore requires specialised pallet handling equipment using ether a specialised forklift or a standard unit a with double deep handling attachment.

However the fork truck used is fitted with telescopic forks to allow the truck to reach into a rack to get a pallet from the rear of a rack.