Rebond team of expert engineers rely on their professional knowledge and extensive experience to perform comprehensive analysis of following 6 common defects in sheet metal forming.

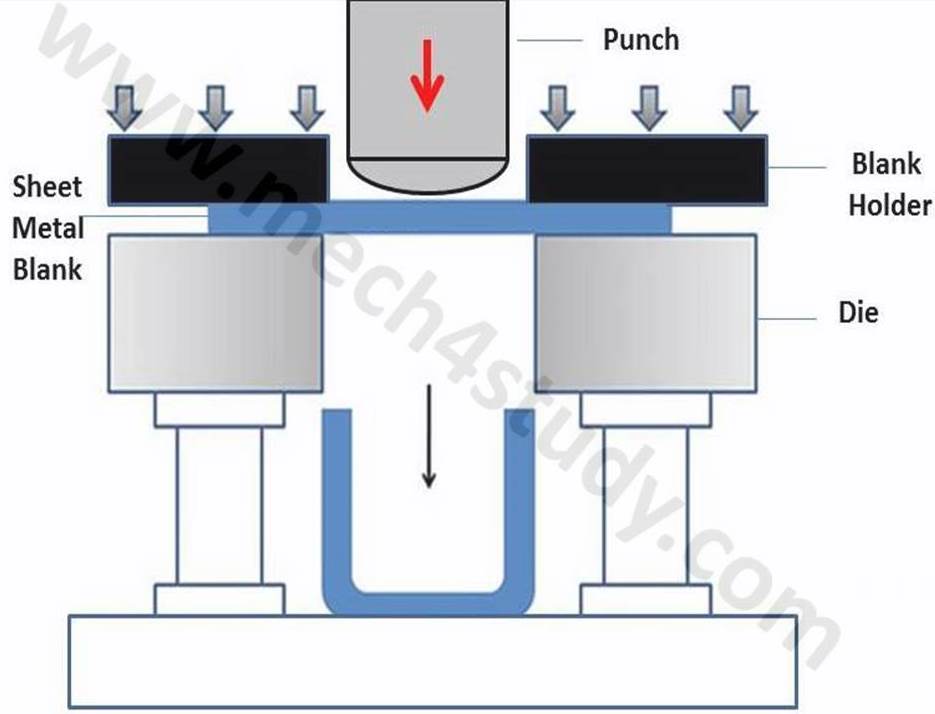

Defects in sheet metal drawing.

Defects in drawing process.

Excessive thinning in areas of the sheet metal is also an unwanted defect.

These defects include draw marks burnishing step rings etc.

Incorrect blank shape and or size.

This defect is caused by non uniform yielding of metal due to non uniform forces.

Wrinkles splits and springback are the three most common defects encountered during sheet metal stamping.

Springback or final part deviation from nominal incorrect process or number of forming tools.

This defect is caused by improper punch die clearance and poor lubrication.

Figure a wrinkling in the flange or b in the wall c tearing d earing e surface scratches basic press working operation sheet metal working is also a metal forming operation where the material being worked is in the form of sheets the working is usually at room temperature.

Excessive thinning thickening of the sheet during forming.

Defects that occur during deep drawing of sheet metal can be controlled by careful regulation of process factors.

This defect is caused by the anisotropy of the sheet metal.

Surface quality plays a very important role in sheet metal forming parts.

The flange of the blank undergoes radial drawing stress and tangential compressive stress during the stamping process which sometimes results in wrinkles.

Causes of these are mostly too high or improper force distribution and material considerations.